1969

Gründung der SCHLOTE GmbH & Co.KG in Harsum mit dem Unternehmenszweck Gussteile aus Metall mechanisch zu bearbeiten.

Gründung der SCHLOTE GmbH & Co.KG in Harsum mit dem Unternehmenszweck Gussteile aus Metall mechanisch zu bearbeiten.

Umzug des Unternehmens in neue Räumlichkeiten, Eintrag der Firma als SCHLOTE & Co. Harsum KG ins Handelsregister. Einführung der zu diesem Zeitpunkt noch neuen CNC-Technologie durch Michael Schlote. Start einer bis heute anhaltenden dynamischen Entwicklung durch die Anschaffung erster CNC-Fräsmaschinen als wesentlicher Bestandteil der Unternehmensentwicklung.

Foto: Christlinde Schlote bei Übernahme der ersten Matchmaker CNC-Maschine zur Bearbeitung von VW-Ölwannen

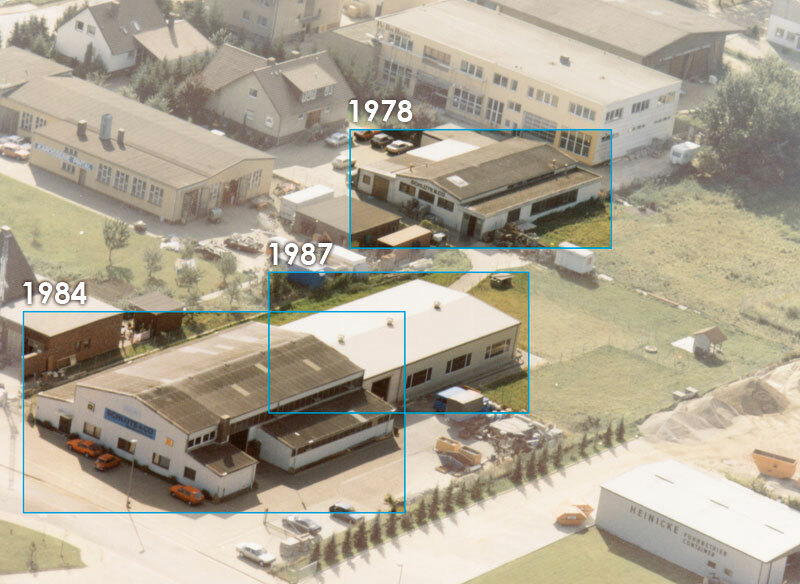

Kauf einer Halle eines benachbarten Landmaschinenhandels zur Erweiterung der Betriebsfläche von 450 auf 1200 Quadratmeter. Der Bezug der neuen Fläche durch die mittlerweile 35 Mitarbeiter erfolgt bereits 3 Monate nach Erwerb. Nur 3 Jahre später folgt die nächste Werkerweiterung auf 1.650 Quadratmeter und beschäftigt 54 Mitarbeiter. Die Inhaber Christlinde und Johannes Schlote investierten weiter in die Modernisierung des Maschinenparks.

Foto: Die Erweiterungsschritte des Firmengeländes in Harsum von 1978 bis 1987

Aus der Rathenower Metallwaren GmbH entsteht die SCHLOTE GmbH Rathenow, die auf eine 30-jährige Erfahrung zurückblicken kann. Hier entstehen Druckgussformen für Aluminium-, Magnesium- und Zinkbauteile.

Die Firma SCHLOTE FormTec GmbH entsteht aus dem ausgegliederten Werkzeug- und Vorrichtungsbau der SCHLOTE GmbH & Co. KG in Harsum.

Aufnahme des Unternehmens Getriebe- und Antriebstechnik Wernigerode GmbH in die SCHLOTE GRUPPE.

Foto: Werksansicht

Mit der SCHLOTE Automotive Czech s.r.o. wird der erste Standort im Ausland gegründet. Das Werk befindet sich in Uherské Hradiště, zwischen den Gebirgen „Weisse Karpaten“ und „Chřiby“.

Gründung der SCHLOTE Brandenburg GmbH & Co. KG, eine der modernsten und innovativsten Fertigungsstätten für einbaufertige Gehäusekomponenten entsteht.

Baubeginn für die Erweiterung des Verwaltungsgebäudes in Harsum, einer neuen Fertigungszufahrt, eines neuen Platzes für die Lagerung der Späne-Container, einer Verdampfungsanlage sowie einer verbesserten Verkehrsanbindung.

Gründung der SCHLOTE Holding GmbH in Harsum als Verwaltungsgesellschaft aller Werke der SCHLOTE GRUPPE.

In nur zwei Jahren entsteht der erste außereuropäische Standort ist in der chinesischen Wirtschaftsmetropole Tianjin – etwa 200km südlich von Peking. SCHLOTE Automotive Parts (Tianjin) Co., Ltd. in Tianjin (China) wird gegründet.

Gründung der Schlote Harzgerode GmbH. In Kooperation mit der Trimet Automotive Holding GmbH (Aluminiumhersteller) entsteht eine der modernsten Produktionsstätten für die Bearbeitung von Getriebe- und Kupplungsgehäusen in Europa.

Foto: Produktionshalle Harzgerode

Schlote Holding GmbH platziert 6,75 %-Unternehmensanleihe 2019/2024 im Volumen von 25 Mio. Euro Schlote Gruppe dringt in den Markt der Sonderanlagenbau vor. Die Betriebstätte in Velbert wird in die Schlote Rathenow GmbH Betriebsstätte integriert.

When Schlote established the first operation in Hildesheim-Bavenstedt, precision component manufacturers for the automobile industry were few and far between. Many of today’s cars have a bit of Schlote in them. The company group based in Harsum has made a global name for itself as a manufacturer of complex motor, transmission and chassis components. Schlote is among Europe’s market leaders for transmission and turbine housings.

The company had 40 employees in 1989. Around 1600 people work for Schlote today – not just in Harsum, but at a total of nine other sites. Schlote also opened a production facility in China in 2014. “VW asked if we wanted to come along,” Jürgen Schlote recalls. It was a huge opportunity but also a major challenge. Since the Wolfsburg company is a key customer for the manufacturer of components for the automobile industry, it was difficult to say no. Ultimately the group took the step to Asia, in part based on the firm conviction that new challenges always harbour opportunities for the company’s further development.

Precision is Schlote’s strength. “There are few competitors in Europe with comparable expertise in the production of precision components for complete systems,” the CEO says. For example, Schlote produces turbine, transmission and clutch housings, exhaust manifolds and mounting brackets in series in its plants. Customers include Volkswagen, Audi, BMW and Daimler as well as ZF, Trimet, Continental and Georg Fischer. Many components come to Schlote from foundries as blanks for further processing. “We rely on innovative technologies, in particular modularisation and automation,” the CEO explains. The vehicle components are machined in what are called processing centres, mostly fully automated. With the most modern lines, only a single employee is responsible for monitoring. Nevertheless, more than 250 employees work in production, which operates in four shifts. “The group produces around 4.5 million transmission housings per year,” says Schlote. Many of the 14 million or so vehicles registered in the EU within a year therefore contain parts made by Schlote.

The company has developed rapidly in more than fifty years. Schlote now has around 400 employees in Harsum. An employee monitors the automated processing steps on a transmission housing.

Jürgen Schlote does not consider this growth to be particularly notable. “We merely seized the opportunities that presented themselves,” the 55-year-old graduate economist says. Schlote took advantage of reunification, the new markets in Eastern Europe a few years later and the outsourcing trend in the automobile industry. “Hardly any other precision manufacturers existed at the time,” Schlote says. His parents Christlinde and Johannes established the first site in Hildesheim-Bavenstedt in 1969. A plant was constructed in Rathenow after the fall of the Berlin Wall. Wernigerode was added in 1996, followed by the expansion to the Czech Republic in 2003 and Tianjin in China three years ago, where Schlote invested around 60 million euros in a new plant. Schlote is currently building a new plant in Harzgerode. This cooperative project between the Harsum-based company and the aluminium producer Trimet Aluminium SE will create about 100 new jobs. Total investments are around 35 million euros. No small sum for a group of companies expected to generate some 250 million euros in sales this year. That being said, Schlote usually concludes contracts with a five to seven-year term with its customers. While this ensures a certain level of planning reliability, it does not entirely safeguard the investments. Rapid growth also harbours risks, for instance when the start-up of a new plant is more difficult than planned. This was the case at the site in China. “Coming into contact with this entirely foreign culture for the first time is far from easy,” Jürgen Schlote says. The CEO is glad that everything is now running smoothly in the plant with around 220 employees. A plant manager was found who previously worked for a German company for 20 years, and thus knows both cultures well and brings them together.

Jürgen Schlote manages the Schlote Group’s business jointly with Carsten Schulz. Both of them can live with setbacks when they are the result of new or bold decisions. A modern company cannot afford to simply keep doing what it has done in the past. Schlote therefore launched a process almost two years ago to strengthen the company’s position for the coming decades. “After so many years of growth, many employees no longer knew what goals we wanted to achieve.” Public awareness of Schlote also had to be increased, not least because of competition for skilled workers. Ultimately the vision was defined: “Success through innovative technology”. This is the guiding principle. Schlote wants to improve itself in several areas in order to reach this goal. “The aim of the new strategy is to provide our employees with orientation without confining them,” Jürgen Schlote explains. Aside from the strategy process, the company also introduced workplace health management. Following the results of an anonymous survey of all employees conducted by Barmer Krankenkasse, Schlote intends to implement specific measures. Workloads could at times be reduced on a case-by-case basis, company sports may be offered or also information to make employees aware of possible health hazards in a timely manner.

The CEO associates the vision with the goal to try new things. “Change has to become a permanent part of what we do, to become normal. That is essential in order to remain competitive in the global market over the long term,” Schlote is convinced.